Izizipholisi ze-oyile ezisetyenziswa kwisixokelelwano samanzi

Eminye imimandla yesoradiator igutyungelwe.Ngenxa yobuchule bayo bokuvelisa, i-soradiator ivelisa uluhlu olubanzi lweemveliso.Kubandakanya izipholileyo ezincinci ze-oyile ezisetyenziswa kwiinkqubo zamanzi.Le mveliso ineempawu zobukhulu obuncinci kunye nokumelana noxinzelelo oluphezulu.Zonke iinkcukacha zibonisa inkqubo yemveliso ye-siradiator ephezulu kakhulu.

Izipholileyo ezincinci ze-oyile ezisetyenziswa kwiinkqubo zehydraulic zizitshintshi zobushushu ezidityanisiweyo eziyilelwe ukususa ubushushu obugqithisileyo kulwelo olusebenza ngolwelo olwenziwa ngamanzi.Ngokuqhelekileyo ziquka uluhlu lweetyhubhu zetsimbi okanye iipleyiti ezinikezela indawo enkulu yendawo yokuhambisa ubushushu.I-hydraulic fluid ihamba ngale mibhobho okanye iipleyiti, ngelixa indawo yokupholisa, efana nomoya okanye amanzi, idlula phezu kwendawo yangaphandle ukuze ikhuphe ubushushu.

Ezi zipholileyo zeoyile zihlala zixhotyiswe ngamaphiko okanye ii-turbulators kumphezulu wangaphakathi wetyhubhu okanye iipleyiti zokuphucula ukuhanjiswa kobushushu.I-Fins yandisa indawo ekhoyo yokutshintshwa kobushushu, ngelixa ii-turbulators ziphazamisa ukuhamba kwamanzi, zikhuthaza ukuxuba okungcono kunye nokutshintshwa kobushushu.

Izizipholisi ze-oyile ezincinci zihlala zidityaniswe kwisekethe yenkqubo yoxinzelelo loxinzelelo olukhulu, nokuba ziiyunithi ezizimeleyo okanye njengenxalenye yereservoir okanye indibano yesitshintshi sobushushu.Banceda ukugcina amaqondo okushisa asebenzayo ngokuthintela i-hydraulic fluid ekugqithiseni, oku kunokukhokelela ekunciphiseni ukusebenza kwenkqubo, ukugqoka icandelo, kunye nomonakalo onokwenzeka.

Ezinye izinto ezincinci zokupholisa i-oyile zinokubandakanya iimpawu ezongezelelweyo, ezinje ngeevalvu ze-bypass okanye izinzwa zobushushu, ukulawula ukuhamba kolwelo okanye ukujonga ubushushu bokusebenza.Ezi zipholileyo ziza ngokobukhulu obahlukeneyo kunye nolungelelwaniso ukuze zihambelane neemfuno zenkqubo yoxinzelelo lwehydraulic eyahlukeneyo, zibonelela ngokupholisa okusebenzayo kuyilo olubambeneyo kunye nokugcina indawo.

Kwezinye iiradiator zesiko, i-soradiator ineworkshop yayo yomatshini, enokuthi ihlangabezane ngokupheleleyo neemfuno zokwenza ngokwezifiso zabathengi.Iyakwazi ukulungelelaniswa ngokupheleleyo ngokuhambelana nokusingqongileyo, uxinzelelo, ubude, umlomo, umthamo we-ventilation, izinga lokuhamba, ukuxhathisa ukothuka, ubungakanani bofakelo, isikhuselo sokukhusela, njl njl ezifunwa ngabathengi.

Kwangaxeshanye, inokuvelisa iiradiyetha koomatshini bezolimo namahlathi.Olu hlobo lwe-radiator luneempawu zokudityaniswa kwemisebenzi emininzi.I-radiator ipholiswe ngamanzi kwelinye icala kunye ne-oyile-ipholile kwelinye.Ngelixa iqinisekisa ukusebenza kakuhle, icinezela kakhulu indawo.

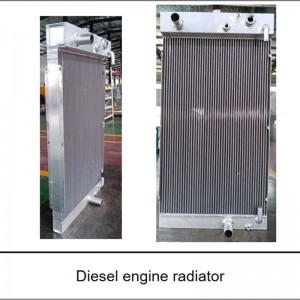

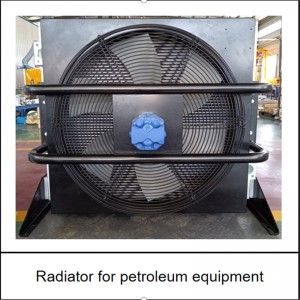

Kukwakho neeradiyetha ezisetyenziswa kwiinjini zedizili.Iiradiator ezisetyenziselwa izixhobo zepetroleum, ezinye iiradiyetha, njl.

Okubandakanya inkqubo yokuwelda ye-argon ye-argon ye-soradiator.Yonke i-soradiator welder inezakhono ezibalaseleyo ze-argon welding eziqokelelwe ngaphezu kweminyaka elishumi.Inokuqinisekisa umgangatho we-welding kunye nokubonakala kowona mlinganiselo mkhulu.Kwiimveliso zoxinzelelo oluphezulu, i-soradiator ithatha itekhnoloji ye-core chamfering + ukungena kwangaphakathi kwe-welding + i-welding-pass-welding ngaxeshanye.Lo mgangatho wolawulo we-welding unokuqinisekisa umgangatho woxinzelelo lwe-welding yeemveliso.Ireyithi yokupasa yokuqala yovavanyo lokuqina kwegesi ye-argon welding ihlala ingaphezulu kwama-92%.

Iphuhliswe ngokusekwe kubuchwephesha obuhamba phambili kwimarike, iiModyuli zokuPholisa ezohlukeneyo zezixhobo zokwakha ziye zamkelwa ngokuthe ngcembe ngabathengi abanomgangatho ongqiniweyo wentengiso.Imodyuli yokupholisa ye-All-in-one yenza ukuhamba komoya okugudileyo kunye nokusebenza okuphezulu kwe-thermal kunye nokuqina ngenxa indibaniselwano yeBar & neePlates.

Abatshintshi bokushisa baphuhliswa kwizinto ezibandakanya i-aluminium kunye ne-coopers, kwiimeko ezikhethekileyo zokusebenza.Iimodyuli zokupholisa kwezoLimo nazo ziphuhlisiwe kunye neBar & Plate.